InspectorX

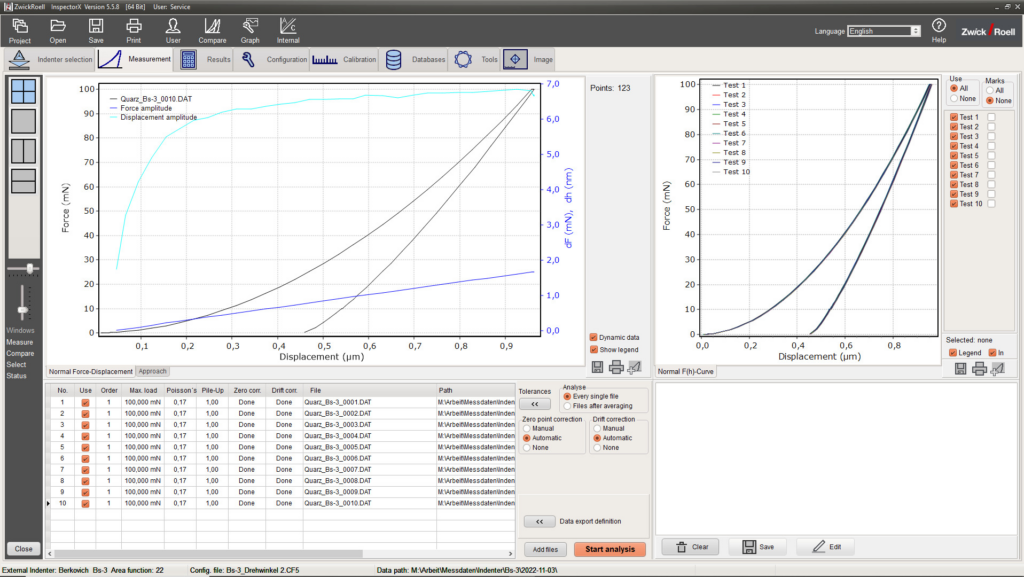

The software for evaluating indentation measurements

InspectorX is the only instrument independent software for the analysis of depth sensing indentation measurements (IIT) with Nanoindenters as well as Macroindenters with a multitude of functions.

Essential functions of InspectorX

- Simultaneous reading, presentation and analysis of up to several hundred indentation measurements.

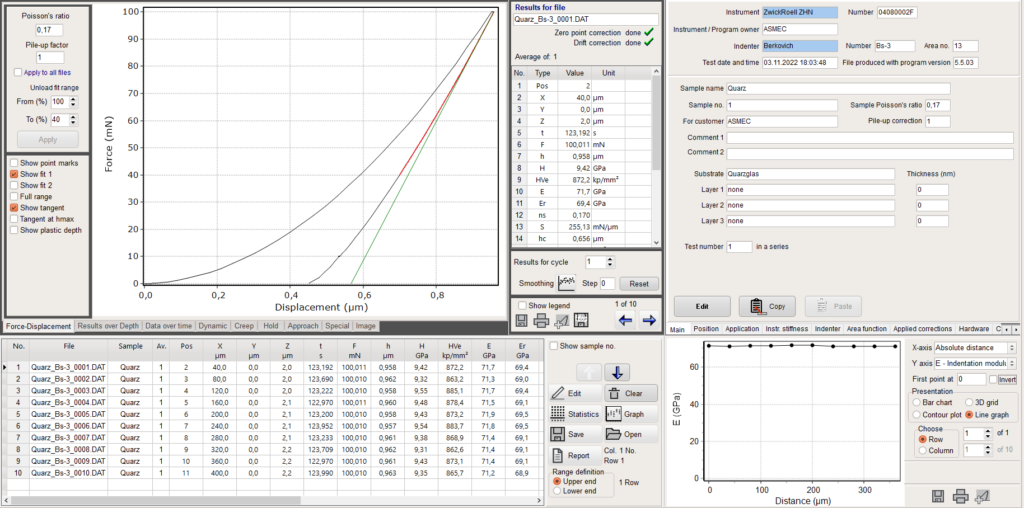

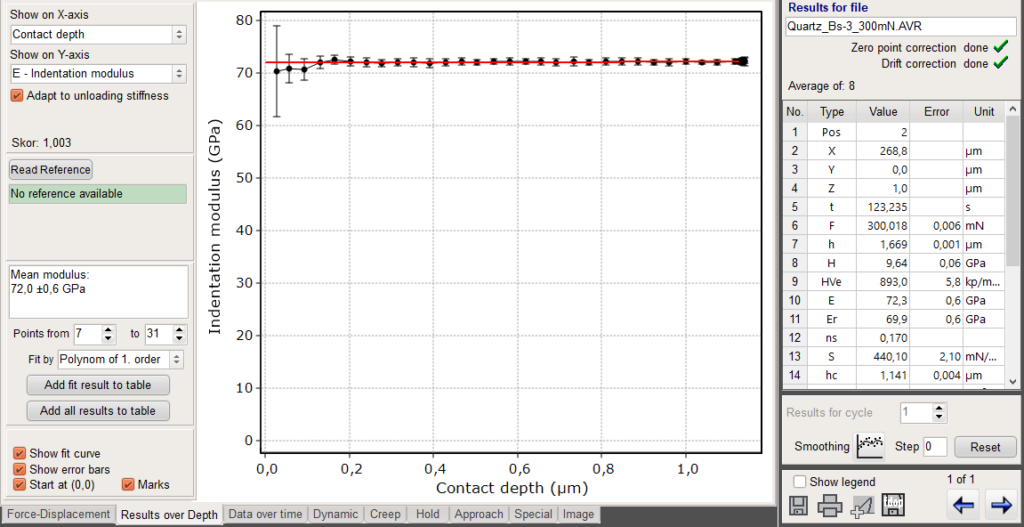

- Analysis of indentation modulus, indentation hardness, Martens hardness, equivalent Vickers hardness, indentation creep, energies according to DIN EN ISO 14577 and more than 60 additional parameters.

- Zero point correction automatic or manual.

- Thermal drift correction automatic or manual.

- Radial displacement correction and variable epsilon factor.

- Averaging of measurements with equal load and equal sequence, even for different number of data points.

- Clearly arranged presentation of results with statistics in a table, a graph or as report

- Export of data in different image formats, as text, in EXCEL, XML or HTML format

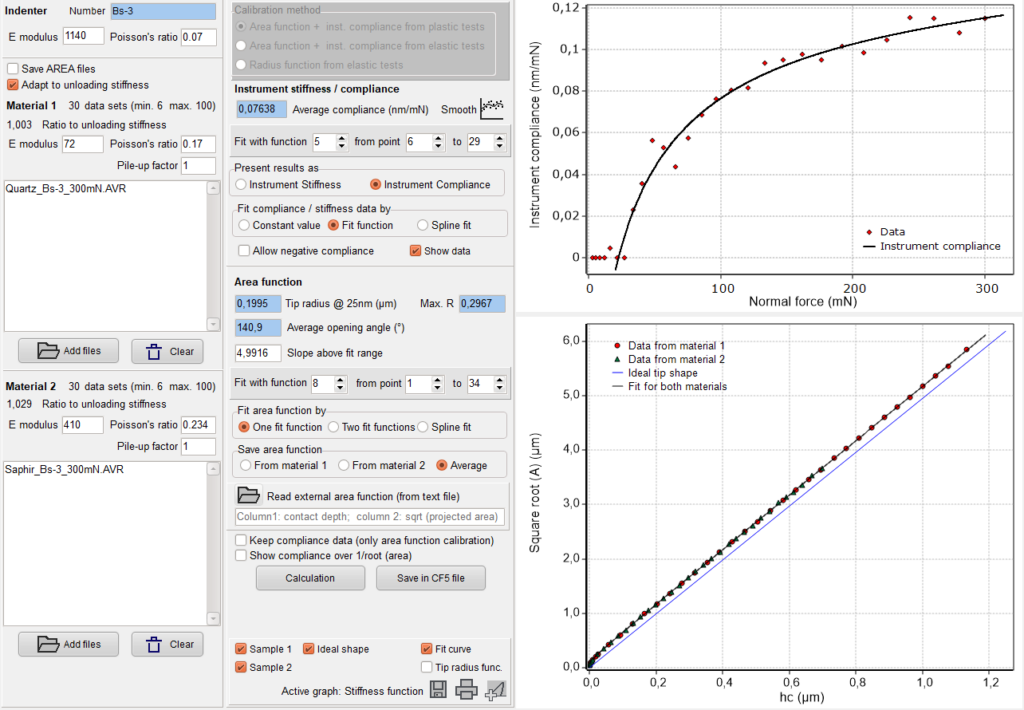

- Determination and correction of instrument stiffness or compliance

- Determination and application of indenter area function or radius function (for spherical tips) with maximum two reference materials.

- Analysis or purely elastic measurements with spherical tips and complete elimination of the substrate influence for the calculation of the Young’s modulus. T herefore this module can be applied to measurements of ultra−thin and hard coatings of only 20nm or less.

- Analysis of creep behavior and calculation of creep rate

- Modeling of force−displacement curves (loading and unloading) after specification of force, indentation hardness and modulus, also under consideration of the real area function.

- Analysis of dynamic measurements with continuous or quasi−continuous stiffness measurements (CSM) (only UNAT, ZHN, Nanoindenter XP und G200)

- Analysis of lateral force−displacement measurements (only UNAT and ZHN) for example in scratch or wear tests.

- Materials database with parameters like E−modulus, Poisson’s ratio, density, yield strength, thermal expansion and other for about 630 materials.

Um die Daten auswerten zu können, ist bei den meisten Geräten eine Umwandlung in Textformat notwendig. Dies erfolgt über die jeweiligen Exportroutinen der Originalsoftware. Die Bedienungsanleitung gibt dazu Hinweise.

The software is applicable to data from the following commercial instruments

- ASMEC UNAT (no text format necessary)

- CSM / Anton Paar NHT/UNHT

- Elionix ENT−1100

- Helmut Fischer Fischerscope (all instruments, DOS or Windows data format)

- Hysitron, all instruments

- Keysight/Agilent Nanoindenter XP/G200

- Micro Materials Nanotest

- Shimadzu DUH−202

- Shimadzu DUH−W201

- UMIS−2000 (DOS and Windows data format, no text format necessary)

- Zwick ZHN (no text format necessary)

- Zwick ZHU

Further data from different non−commercial research instruments can be read.

Download

After installation this software is only working as trial version with limited rights.

You have the option to test the software as full version for a period of 30 days. You only need to click on our email address in the Welcome window and to add the missing data in the prepared email.

After purchasing the software you will get an access code for an unlimited period.