Software

ASCMEC develops fast and precise software in the field of surface mechanics

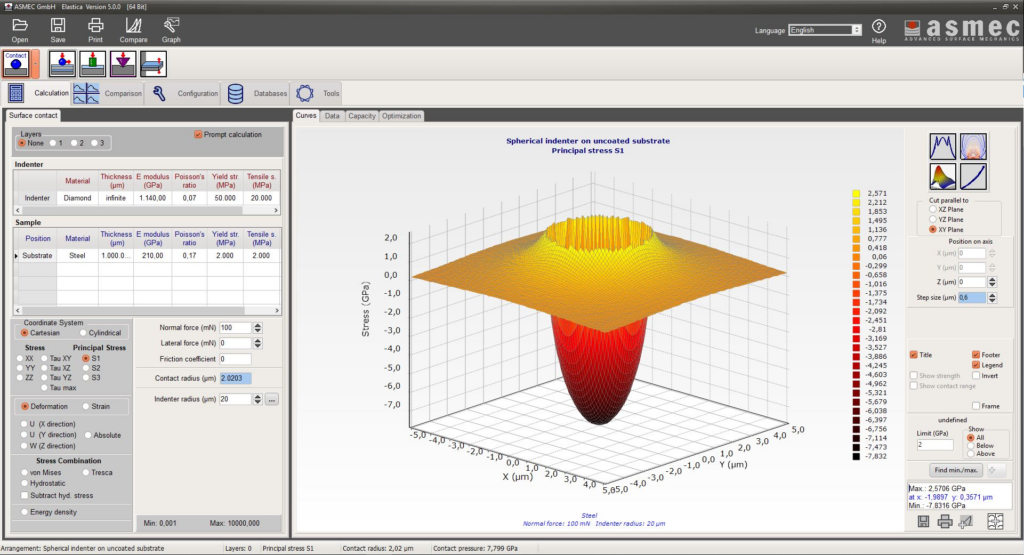

Elastica®

Elastica is a user-friendly software for fast and precise calculation in contact mechanics. It is ideal for the analysis of coated materials and offers up to 1000 times faster performance than conventional methods. The software can analyse different layers and complicated contact problems, and although it is based on idealised assumptions, it provides very useful results in practice.

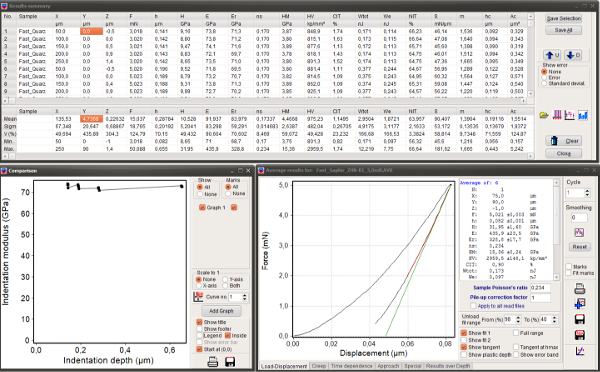

InspectorX®

InspectorX is a versatile and device-independent software for evaluating indentation measurements made with nano and macro indenters. It offers a wide range of functions, from the evaluation of various hardness parameters to thermal drift correction. The software can simultaneously read and evaluate hundreds of measurements and offers a range of export options. It also comes with a comprehensive material database. It is compatible with a wide range of series instruments and can also process data from various research instruments. Most devices require data to be converted to text format, for which the original software provides appropriate export routines.